ERP Integration & Process Automation for Leading Textile Manufacturer

Streamlined operations and reduced manual work by 75% through custom ERP integration and automated workflows for a 500+ employee textile manufacturing company.

Client

Gujarat Textiles Ltd

Textile Manufacturing

Duration

8 months

Team Size

6 specialists

Location

Ahmedabad, Gujarat

Before & After Transformation

See the dramatic improvements achieved through our strategic approach and technical expertise.

Manual inventory tracking with paper-based processes

Use the tabs above to compare the transformation, or view side-by-side below:

Measurable Results Achieved

Our data-driven approach delivers tangible improvements that directly impact business growth and operational efficiency.

Why These Results Matter

These metrics represent real business impact achieved through strategic planning, technical expertise, and continuous optimization. Each improvement translates to increased revenue, reduced costs, enhanced customer satisfaction, and sustainable competitive advantage for our clients.

The Challenge

The client was struggling with disconnected systems, manual data entry across multiple departments, inventory discrepancies, and delayed reporting that impacted decision-making and operational efficiency. **System Integration Issues:** - Multiple disconnected software systems across departments - Manual data entry leading to errors and inconsistencies - No real-time visibility into production and inventory status - Delayed reporting affecting critical business decisions **Operational Inefficiencies:** - Order processing taking 3-5 days due to manual workflows - Inventory discrepancies causing production delays - Quality control processes not integrated with production systems - Financial reporting requiring manual data compilation from multiple sources

Our Solution

Implemented comprehensive ERP system integration connecting production, inventory, sales, and accounting

Developed custom APIs to sync data between legacy systems and new ERP platform

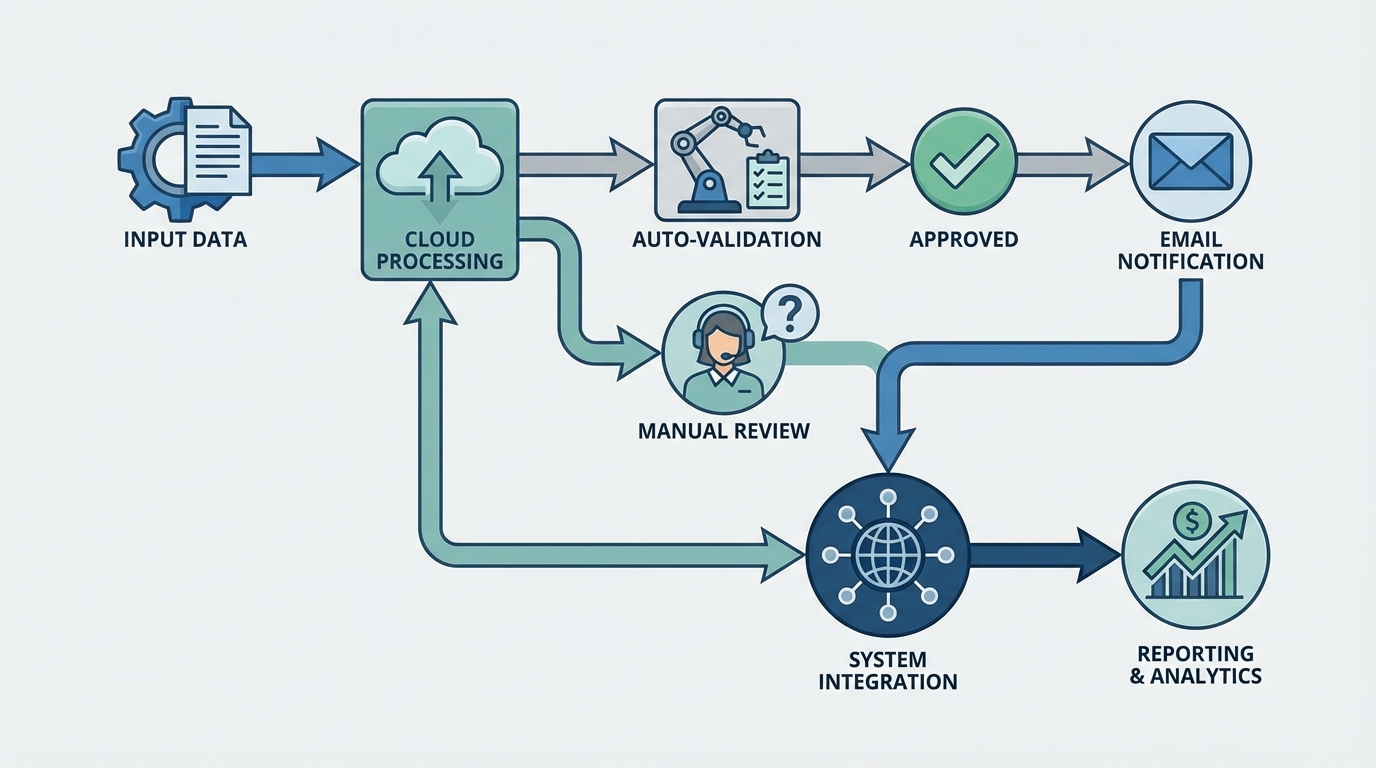

Created automated workflows for order processing, inventory management, and quality control

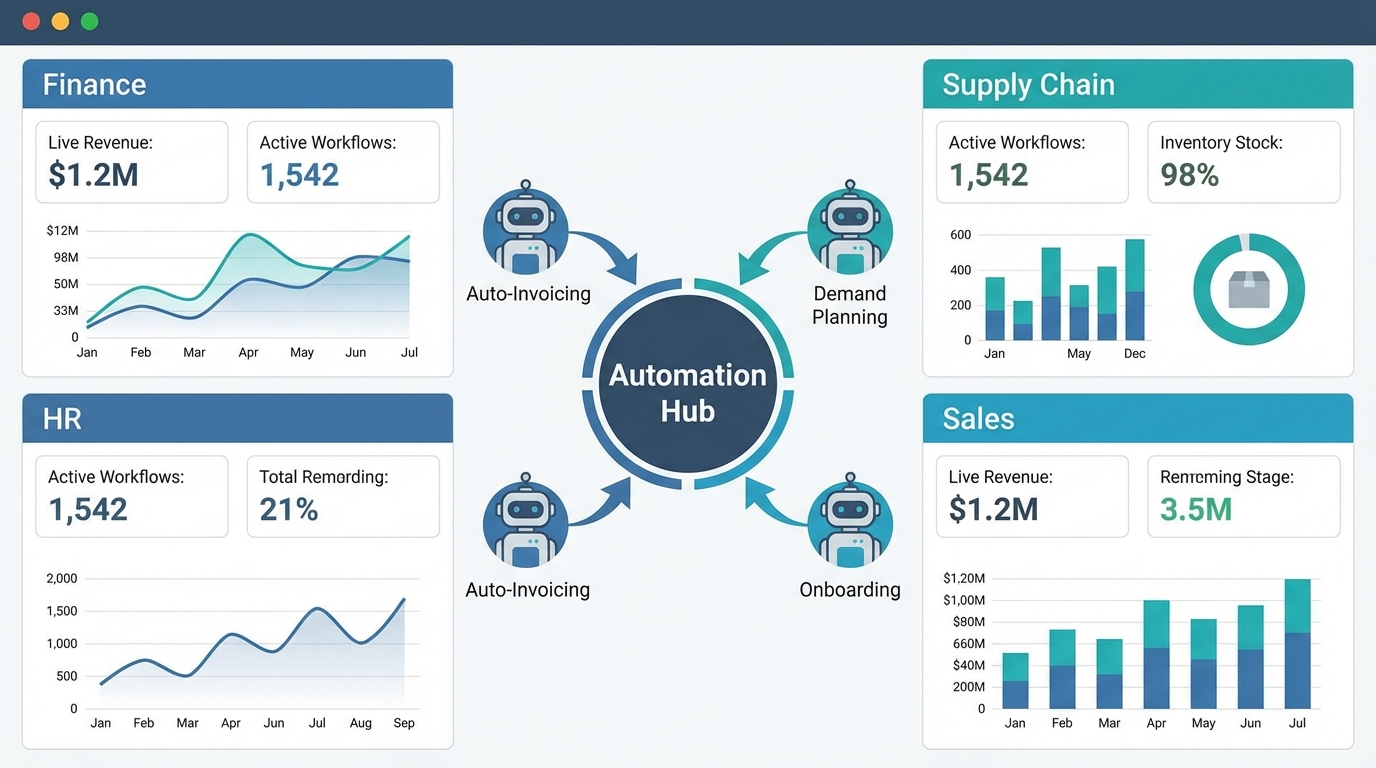

Built real-time dashboards for production monitoring and business intelligence

Integrated quality control systems with production workflows for automated compliance tracking

Built real-time dashboard for management reporting and KPI tracking

Implemented barcode scanning system for inventory and production tracking

Project Overview

Gujarat Textiles Ltd, a leading textile manufacturer in Ahmedabad with over 500 employees, approached us with significant operational challenges. Their disconnected systems were causing inefficiencies, manual errors, and delayed decision-making that impacted their competitive edge in the fast-paced textile industry.

The Challenge

The company was operating with multiple disconnected systems:

- Legacy inventory management system

- Separate accounting software

- Manual production tracking

- Excel-based reporting

- Disconnected sales and order management

This fragmentation led to:

- Data inconsistencies across departments

- Manual data entry errors costing thousands monthly

- Delayed reporting affecting strategic decisions

- Inventory discrepancies impacting customer satisfaction

- Inefficient resource allocation due to lack of real-time visibility

Our Solution Approach

We implemented a comprehensive digital transformation strategy:

Phase 1: System Analysis & Integration Planning

- Conducted thorough audit of existing systems

- Mapped current business processes and identified bottlenecks

- Designed integration architecture for seamless data flow

- Created migration strategy with minimal business disruption

Phase 2: ERP Implementation & Custom Development

- Deployed SAP Business One as the central ERP system

- Developed custom APIs for legacy system integration

- Created automated workflows for key business processes

- Built real-time dashboards for different user roles

Phase 3: Process Automation & Training

- Implemented barcode scanning for inventory tracking

- Automated order-to-cash and procure-to-pay processes

- Created automated quality control checkpoints

- Conducted comprehensive staff training and change management

Key Results Achieved

The transformation delivered measurable improvements across all operational areas:

Operational Efficiency

- 75% reduction in manual data entry work

- 3x faster order processing times

- 99.2% inventory accuracy (up from 78%)

- Real-time visibility into all business operations

Financial Impact

- ₹2.5 lakhs monthly savings from reduced manual errors

- 30% improvement in cash flow through faster invoicing

- 20% reduction in inventory holding costs

- ROI achieved within 14 months

Strategic Benefits

- Real-time reporting enabling data-driven decisions

- Scalable system supporting business growth

- Improved customer satisfaction through accurate delivery promises

- Enhanced compliance with automated audit trails

Technology Implementation

Our solution leveraged modern technologies for maximum efficiency:

- SAP Business One: Core ERP system for integrated business management

- Custom APIs: Seamless integration between systems

- React Dashboard: User-friendly interface for real-time monitoring

- PostgreSQL: Robust database for data integrity

- Power BI: Advanced analytics and reporting capabilities

- Barcode Integration: Automated inventory and production tracking

Client Testimonial

"The team at Dhīmahi Technolabs didn't just implement software – they transformed how we work. Our managers now have real-time insights, our staff is more productive, and our customers are happier with accurate deliveries. The ROI has exceeded our expectations."

Rajesh Patel, Operations Director, Gujarat Textiles Ltd

Long-term Partnership

Post-implementation, we continue to provide:

- 24/7 system monitoring and support

- Regular system updates and enhancements

- Staff training for new features

- Performance optimization based on usage patterns

- Strategic consulting for future growth initiatives

This case study demonstrates our expertise in complex ERP integrations and business process automation, helping traditional manufacturers embrace digital transformation for sustainable growth.

Services Utilized

Project Gallery

Streamlined process flow from order to delivery

"Dhīmahi Technolabs transformed our entire operation. What used to take hours now happens automatically. Our team can focus on growth instead of paperwork."

Technology Stack

Modern, reliable technologies used in this project

SAP Business One

ERP System

Node.js

Backend

React

Frontend

PostgreSQL

Database

REST APIs

Integration

Power BI

Analytics

Related Success Stories

Explore more examples of how we've helped businesses achieve similar transformations and drive measurable growth.

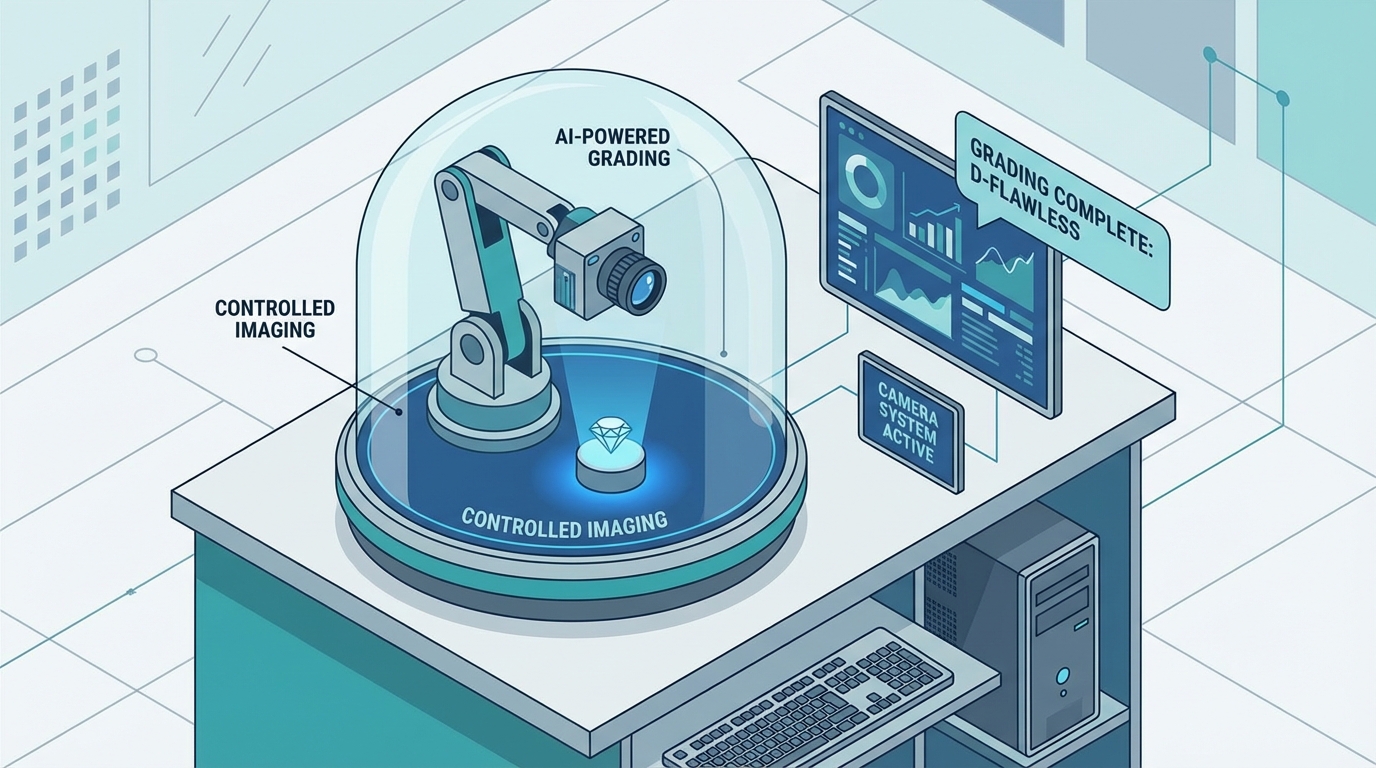

AI-Powered Quality Control for Diamond Processing Unit

Implemented computer vision-based diamond grading system that reduced inspection time by 70% and improved grading consistency to 98.5% for a diamond processing company.

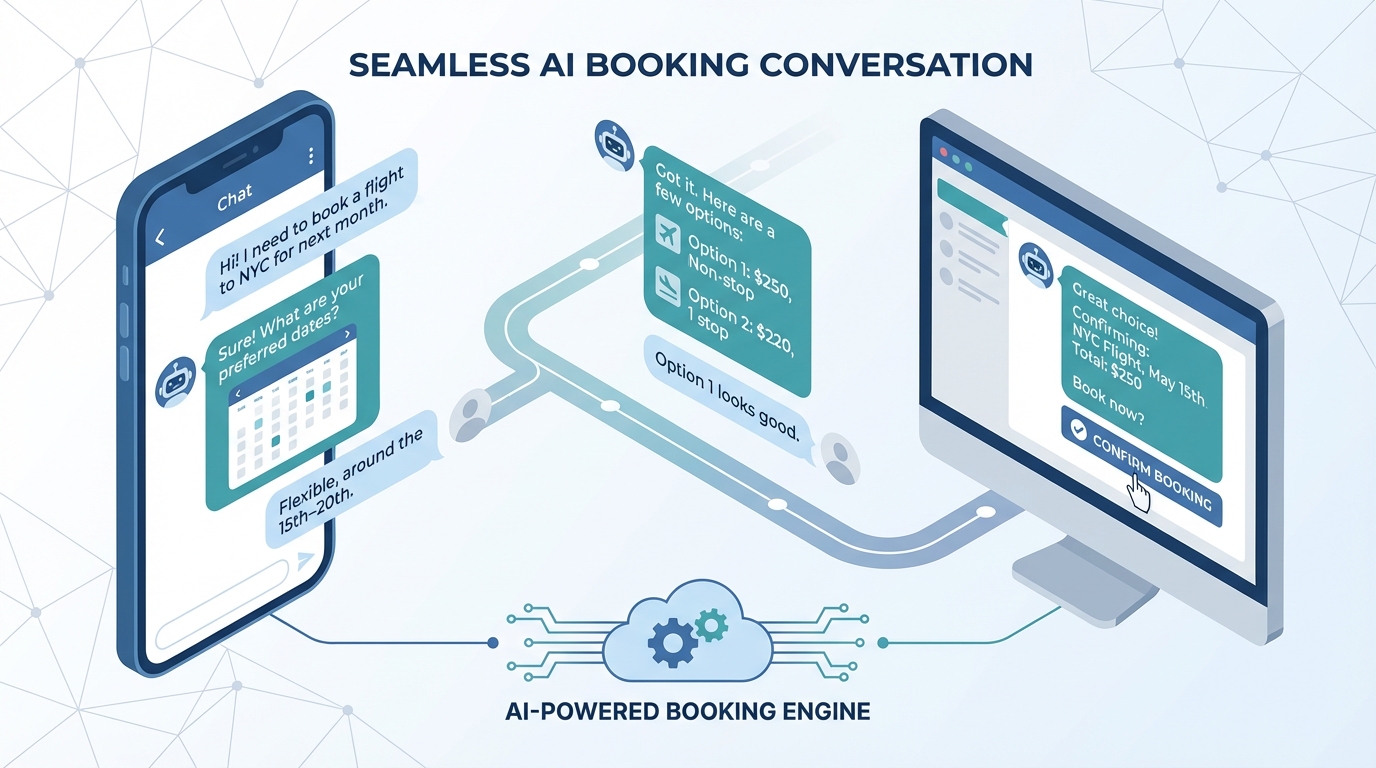

WhatsApp Chatbot & Booking Automation for Hotel Chain

Built AI-powered WhatsApp chatbot handling 80% of guest queries automatically, integrated with PMS for real-time booking, reducing front desk call volume by 65% for a 4-hotel chain.

Automated Invoice Processing for Trading Company

Implemented AI-powered invoice processing that reduced manual data entry by 90% and processing time from 3 days to 4 hours for a commodity trading company handling 2,000+ invoices monthly.

Ready for Similar Results?

Let's discuss how we can help transform your business with proven strategies and cutting-edge technology solutions.